Riverside owns the whole process from quote to delivery, so you get peace of mind.

Our Capabilities

Discover the equipment, technology, and processes that power our precision fabrication and custom manufacturing work.

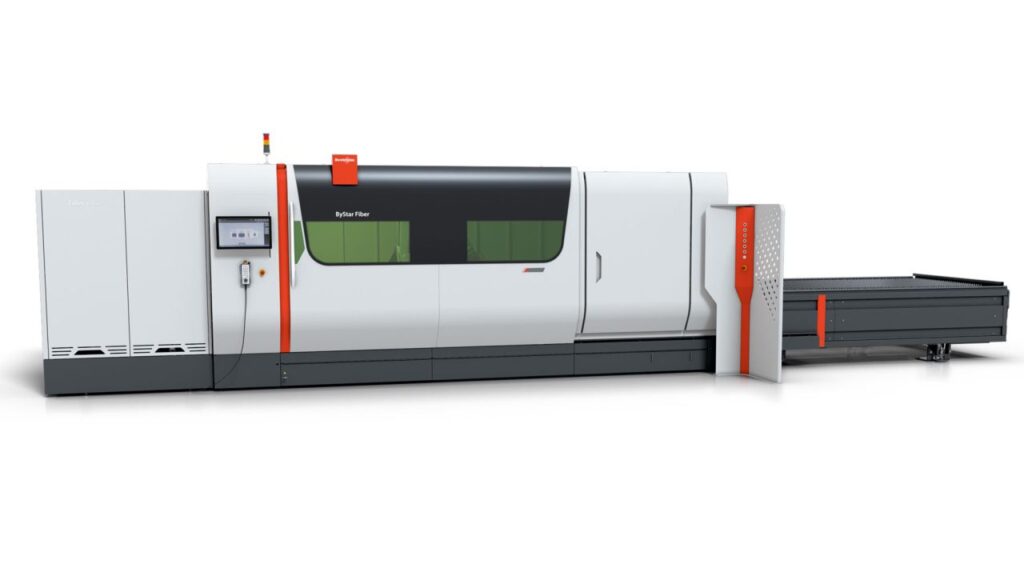

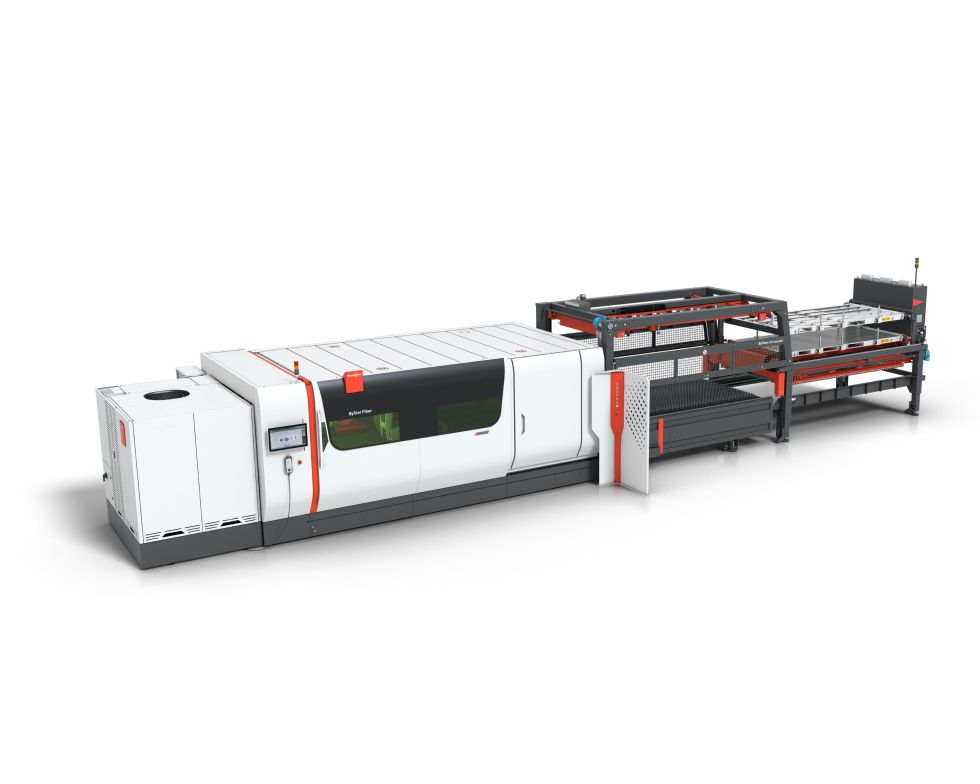

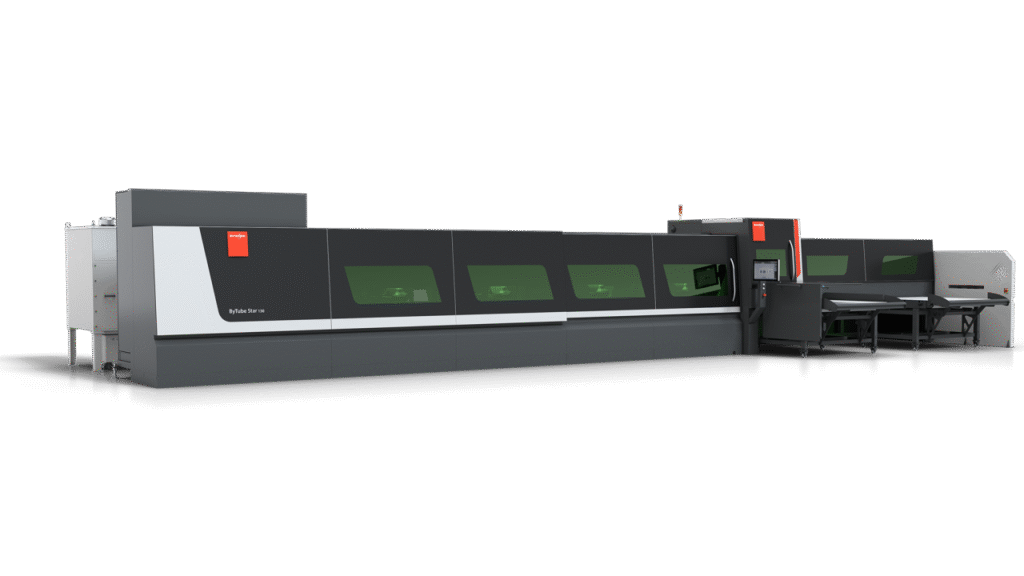

High-precision laser cutting for aluminum, stainless, mild steel, and more. Fast, repeatable, and ideal for detailed work.

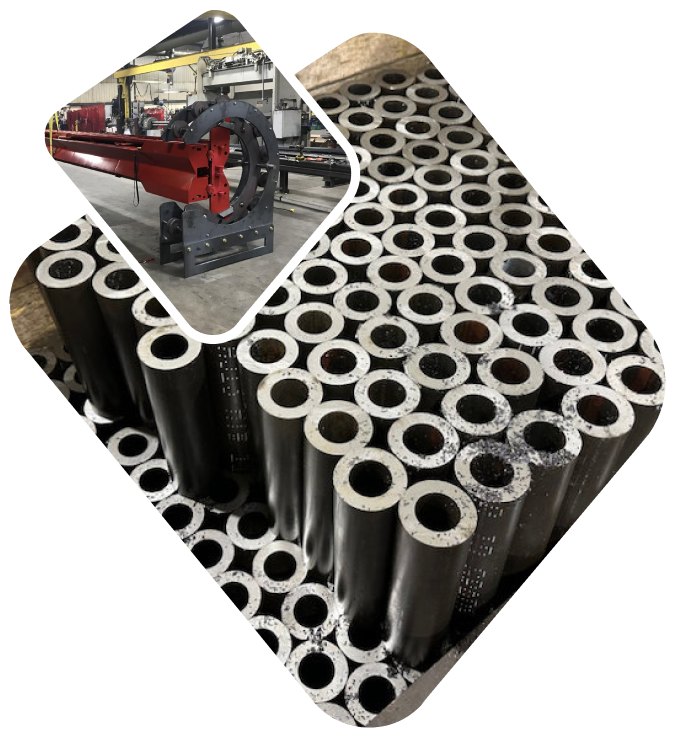

10ft CNC roller, capable of rolling 5/16th” material

4-roll machines offer unmatched precision, productivity, and ease of use. Securely hold the plate, form tight diameters with high accuracy, and support full CNC automation with minimal operator input—ideal for mass production.

Precision stamping for high-volume production of custom metal parts with consistent accuracy and efficiency.

Full-service welding backed by AWS certification. Get precision and durability from our team of __ skilled welders.

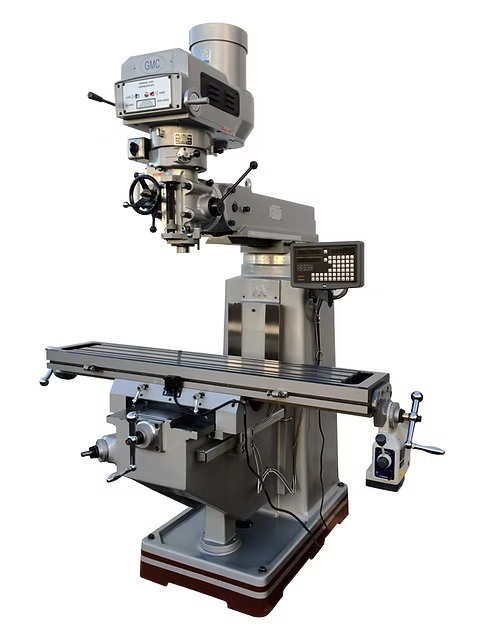

Versatile vertical milling solutions for complex part geometries and tight tolerances.

Get seamless, end-to-end service with Riverside’s fully integrated powder coating line.

Capabilities:

Accurate, clean cuts for a variety of metals, using high-performance band and cold saws.

The S-23A is an automatic scissor-style band saw built for medium-duty cutting. It handles miters from 90° to 60° and can cut up to 16″ high by 20″ wide at 90°.

Powered by an 8.8 HP motor with a 1-1/4″ blade, it features an LED control panel that displays blade speed, tension, and height, motor load, cut time, part length, quantity, and job runtime—with multiple language options.

The FWS50 is a precision cold saw designed for clean, accurate cuts in metal. It uses a high-torque, low-RPM circular blade that minimizes heat and distortion, making it ideal for tight-tolerance applications. Built for repeatable, high-quality cuts.

Capabilities: Tight-tolerance, high-precision machining for complex and simple components.

New: High-speed precision forming for parts of any complexity. We combine automation with decades of experience to meet the demands of high-volume jobs efficiently and accurately.

Compact, high-speed press brake ideal for small to mid-sized parts. Can deliver 80 tons of force, fast cycle times, and precise results in a mobile footprint—perfect for flexible, efficient production.

Designed for flexible, high-accuracy bending. Customizable tonnage and length options, consistent angle accuracy with dynamic crowning and LAMS, capable of integration with automation for lights-out production.

150-ton press brake with a 10-foot bending length, designed for high-precision forming. Featuring dynamic crowning, angle measuring (LAMS), and optional automation—ideal for flexible, accurate, and efficient production.

200-ton press brake with a 4.3-meter bending length. Offering high-precision forming with dynamic crowning, angle measuring (LAMS), and automation-ready options for efficient, flexible production.

Advanced robotic welding for maximum efficiency, consistency, and throughput in high-volume jobs.

We prioritize quality in every project, with leadership directly overseeing the onboarding of new clients and continuous improvements. Our certifications include:

ISO 9001:2015

AWS

Quality You Can Trust.

At Riverside, our quality control is built on three pillars: certification, technology, and innovation. These factors drive our reputation for delivering excellence.

Our team of certified welding supervisors and inspectors diligently verify the integrity of all welding operations

At the end of the day, Riverside’s quality is driven by our dedicated team, and the efficient systems we create.

While offering consistent quality, we look for opportunities to innovate. This creates a pattern of continuous improvement and growth, both for our customer’s businesses, and our own.

When you work with Riverside, you can see the up-to-the-minute status of your parts and projects at all times.

And when your project is finished, Riverside’s experts will conduct a thorough review of your order to make sure you get the part you need—without having to ship anything back.

And whenever any issues arise, you will find out immediately—and learn everything our team is doing to make things right.

More Than Just Fabrication Services—Your One-Stop Shop

As part of our commitment to helping you take advantage of every opportunity, Riverside’s fabrication services are backed by comprehensive value-added services.

Because when you partner with Riverside, you should be free to focus on what you do best and outsource the rest.

Packaging

Assembly services

Inventory control

Shipping

3D Design

Metal Sales