You’ve invested in precision-built parts for your equipment — but what happens if the finish can’t hold up? Rust, chips, and fading can turn a solid component into a weak link, costing you money and downtime. That’s why the decision between powder coating and paint is far more than cosmetic. It’s about protecting your investment and keeping your operation running smoothly.

At Riverside Industries, we specialize in finishes designed to stand up to the toughest conditions — from agriculture fields to oil rigs. We’ve seen how the wrong finish can cut a part’s lifespan short, and we know what it takes to make sure yours last.

Here’s a clear breakdown of powder coating vs. paint so you can make the best call for your business.

Powder Coating vs. Paint: Which Should You Choose?

What is Powder Coating?

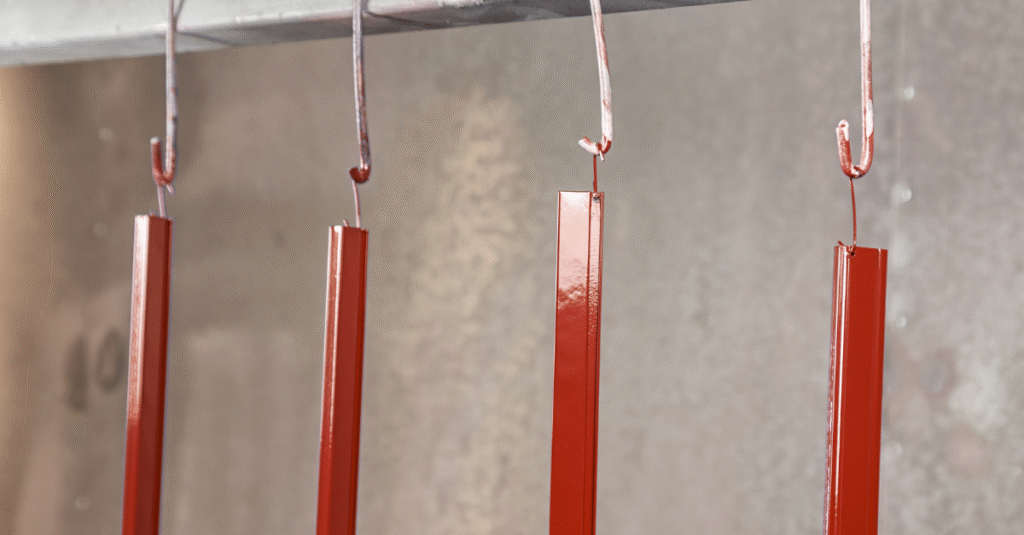

Powder coating is a finishing process where dry powder is applied to a part and then cured in a specialized oven. This creates a dense, uniform layer that bonds directly to the surface, delivering exceptional durability.

Why Manufacturers Choose Powder Coating:

- Built for Durability — Resists scratching, corrosion, and everyday wear.

- Environmentally Safer — VOC-free, with recyclable overspray.

- Consistent Appearance — Smooth, drip-free coating with customizable finishes.

- Saves Money Over Time — Fewer repairs and replacements compared to paint.

At Riverside, our dedicated powder coating line is equipped with tumble and shot blasters to ensure parts are properly prepped. This step is critical — it allows the coating to bond tightly and perform under the harshest industrial use.

What is Industrial Paint?

Industrial paint is a traditional liquid coating that’s sprayed or brushed on, then left to dry and cure. It’s been around for decades and is still common because it’s cost-effective and easier to apply in certain situations.

Why Some Operations Still Use Paint:

- Lower Initial Cost — Requires less setup and equipment.

- Flexible Application — Works on very large parts that won’t fit in curing ovens.

- Easy Touch-Ups — Quick repairs can be made on-site.

Paint can make sense for oversized equipment or when you need a quick turnaround. But in terms of long-term resilience, it often falls short compared to powder coating.

Powder Coating vs. Paint: Key Differences

| Factor | Powder Coating | Industrial Paint |

| Durability | Highly resistant to chips, scratches & corrosion | More prone to wear and fading |

| Environmental Impact | No VOCs, recyclable overspray | VOCs and solvents |

| Finish Quality | Smooth, even, no drips | Brush marks or uneven coverage possible |

| Long-Term Cost | Lower — fewer repairs needed | Higher — frequent repainting required |

| Application Limits | Requires curing oven | Can be applied on-site to oversized parts |

How Riverside Ensures a Better Finish

Riverside’s process is designed for strength, consistency, and efficiency:

- Surface Prep Done Right – Shot and tumble blasting for maximum adhesion.

- Dedicated Coating Line – Built for everything from one-off projects to large production runs.

- Full-Service Fabrication – Because we control the entire workflow (cutting, machining, forming, welding, and finishing), your parts never face quality gaps or supply chain delays.

- ISO 9001:2015 Certified – Every part we finish meets rigorous quality standards.

By managing the entire process in-house, we deliver coatings that are consistent, reliable, and built to perform in the most demanding environments.

Which Finish Should You Choose?

Here’s the short answer:

- Choose powder coating if you need a finish that lasts, looks sharp, and saves money in the long run. It’s the best choice for parts exposed to weather, chemicals, or heavy use.

- Choose paint if you need a quick fix, on-site application, or you’re dealing with oversized equipment that can’t be powder coated.

For most OEMs and industrial operations, powder coating is the clear winner. It provides predictable performance, fewer failures, and lower lifecycle costs.

Invest in a Finish That Lasts

When comparing powder coating vs. paint, it’s clear powder coating delivers the edge your industrial parts need to thrive in tough conditions. At Riverside Industries, we don’t just apply coatings — we back them with decades of fabrication expertise, in-house finishing lines, and a commitment to delivering on time, every time.

Ready to give your parts a finish that’s built to last? Request a Quote from Riverside Industries today and see how our powder coating solutions extend the life — and performance — of your equipment.