Roll Forming Services: Precision CNC Roll Forming for OEM Manufacturing

For OEM manufacturers producing repeatable steel components at scale, roll forming is one of the most efficient and accurate metal forming processes available. When the right equipment and controls are applied, CNC roll forming delivers consistent profiles, tight tolerances, and predictable production output—without the variability of manual forming. What Roll Forming Is Roll forming is […]

What Is Full Service Contract Manufacturing and Why It Matters for Modern OEMs

As supply chains become more complex and customer expectations rise, many manufacturers are rethinking how they build and deliver products. One approach continues to gain traction across industries like agriculture, construction, energy, transportation, and heavy equipment: full service contract manufacturing. This model goes beyond basic fabrication or outsourced labor. It offers a streamlined way to […]

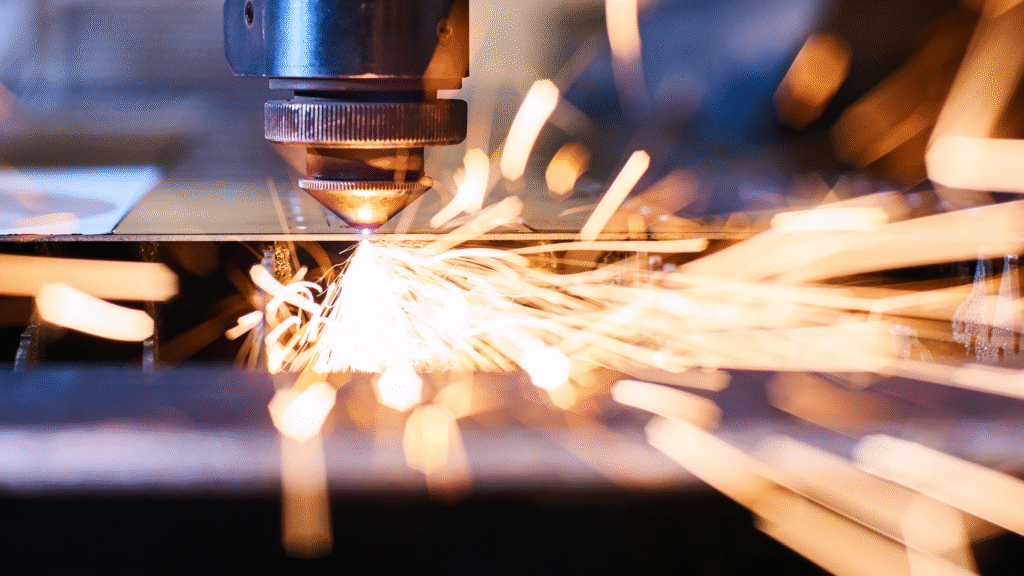

Aluminium Laser Cutting: A Complete Guide to Precision, Speed, and Scalable Manufacturing

Aluminium laser cutting has become a cornerstone process for manufacturers who need precision parts, clean edges, and repeatable results at scale. From OEMs and industrial fabricators to equipment manufacturers and product designers, aluminium laser cutting supports fast production without sacrificing accuracy or quality. This guide explains how aluminium laser cutting works, why it is different […]

MIG Welding Explained: What a MIG Welder Is and When to Use MIG Welding Services

MIG welding is one of the most widely used welding processes in modern manufacturing. From structural frames to high volume production parts, it delivers strong, clean welds at a pace that keeps operations moving. If you have ever searched for a MIG welder or MIG welding services, chances are you are trying to balance […]

Why MIG Welding Remains a Popular Fabrication Method

In metal fabrication, welding determines whether a part holds up in the real world. The welding method you choose affects strength, appearance, production speed, and long-term reliability. That’s why MIG (Metal Inert Gas) welding remains one of the most widely used welding techniques in fabrication today. It’s fast, consistent, versatile, and cost-effective, especially when working […]

Sheet Metal Fabrication Explained: How to Choose the Right Fabricator for Your Project

When a product needs to be strong, precise, repeatable, and scalable, sheet metal fabrication is often the backbone behind it. From agricultural equipment and construction machinery to energy systems and transportation components, fabricated sheet metal parts are everywhere—working hard behind the scenes. But not all sheet metal fabricators are created equal. If you’ve ever searched […]

Mild Steel Laser Cutting: What It Is & Why Manufacturers Use It

Mild Steel Laser Cutting: What It Is & Why Manufacturers Use It Mild steel laser cutting has become one of the most reliable fabrication methods in modern manufacturing. It’s fast, accurate, and cost-effective, making it a smart choice for everything from prototypes to high-volume production. What Is Mild Steel Laser Cutting? Mild steel laser cutting […]

Powder Coating 101: How It Works & Why It’s Common in Manufacturing

When you look at durable finishes on metal parts, there’s a good chance you’re seeing powder coating at work. This finishing technique has become the industry standard for manufacturers who demand both durability and visual appeal. But what exactly is powder coating, and why has it become so popular? What Is Powder Coating? Powder coating […]

What Is Contract Manufacturing?

In today’s competitive business landscape, companies are constantly seeking ways to optimize production while reducing costs. Contract manufacturing has emerged as a strategic solution that allows businesses to focus on their core competencies while outsourcing production to specialized experts. Understanding Contract Manufacturing Contract manufacturing is a business arrangement where a company hires another manufacturer to […]

5 Things to Look for in a Laser Cutting Service

When you’re outsourcing precision parts, your laser cutting service provoder can make or break your production schedule. The right partner delivers clean edges, tight tolerances, and fast turnaround — all without the costly rework that slows down projects. Before you send out your next RFQ, here are five key things to look for in a […]