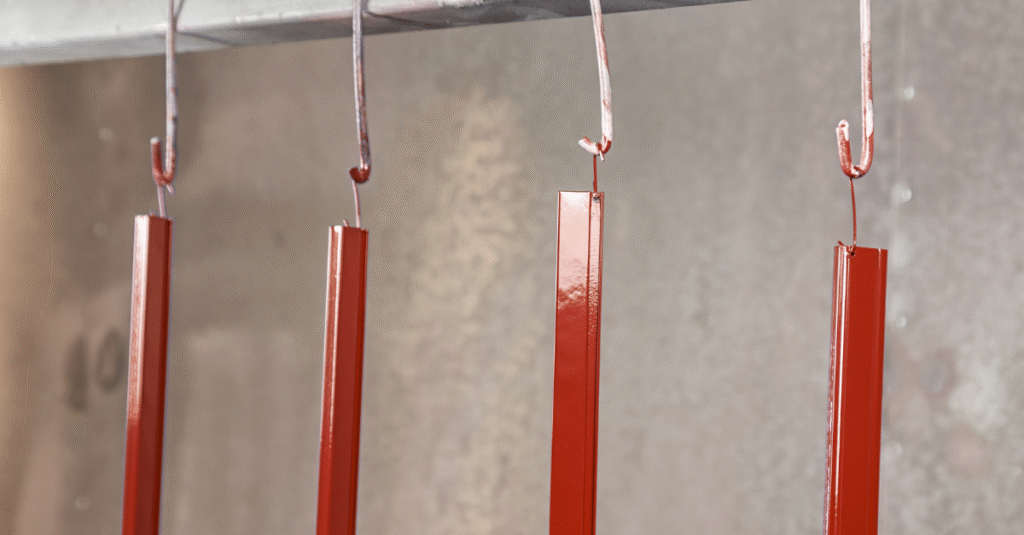

Powder Coating 101: How It Works & Why It’s Common in Manufacturing

When you look at durable finishes on metal parts, there’s a good chance you’re seeing powder coating at work. This finishing technique has become the industry standard for manufacturers who demand both durability and visual appeal. But what exactly is powder coating, and why has it become so popular? What Is Powder Coating? Powder coating […]

What Is Contract Manufacturing?

In today’s competitive business landscape, companies are constantly seeking ways to optimize production while reducing costs. Contract manufacturing has emerged as a strategic solution that allows businesses to focus on their core competencies while outsourcing production to specialized experts. Understanding Contract Manufacturing Contract manufacturing is a business arrangement where a company hires another manufacturer to […]

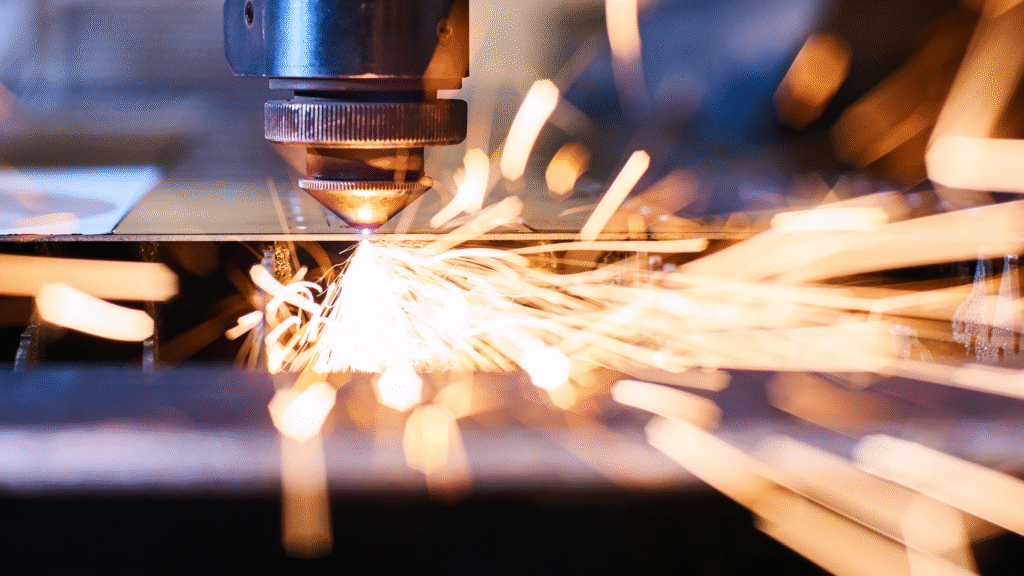

5 Things to Look for in a Laser Cutting Service

When you’re outsourcing precision parts, your laser cutting service provoder can make or break your production schedule. The right partner delivers clean edges, tight tolerances, and fast turnaround — all without the costly rework that slows down projects. Before you send out your next RFQ, here are five key things to look for in a […]

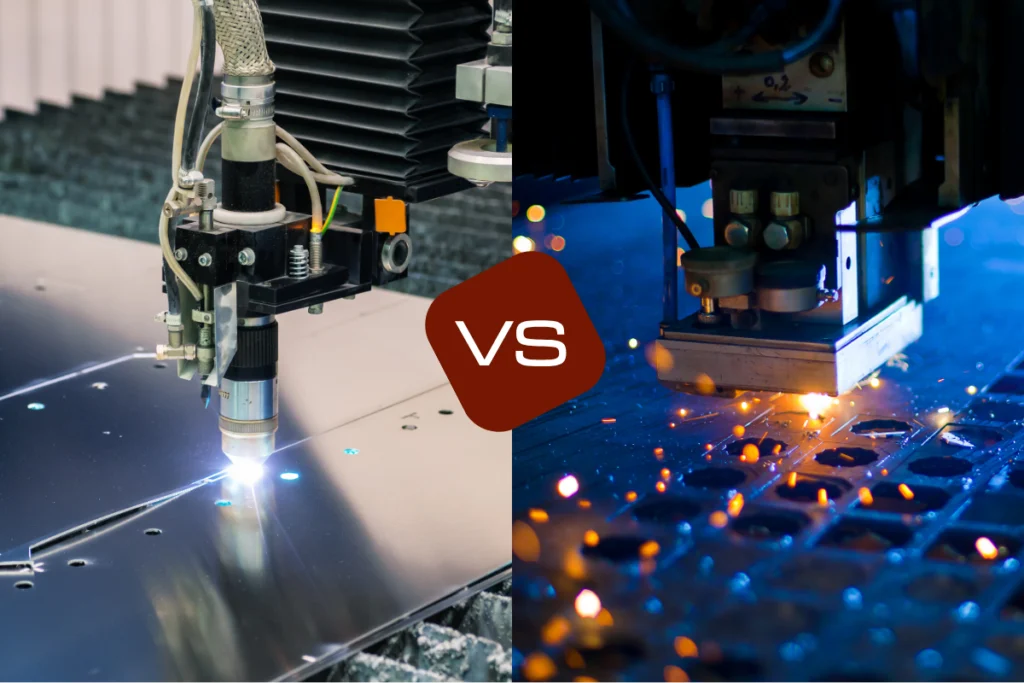

Laser Cutting vs Plasma Cutting: Which is Right for Your Project?

You’ve got a part to produce — but which cutting process will give you the best edge? Many manufacturers wrestle with the laser cutting vs. plasma cutting decision. Both methods promise speed and efficiency, but the wrong choice can lead to wasted material, higher costs, or delays that ripple through your entire supply chain. Imagine […]

Hot Rolled Steel vs Cold Formed Steel: What’s the Difference?

When selecting steel for construction or manufacturing projects, understanding the difference between hot rolled steel and cold formed steel is essential. Each process produces distinct material properties that make them suitable for different applications. What is Hot Rolled Steel? Hot rolled steel is manufactured at extremely high temperatures, typically above 1,700°F (926°C)—well above steel’s recrystallization […]

CNC Tube Forming for Complex Tubular Components

CNC tube forming has transformed how manufacturers shape and produce tubular components. By combining computer-controlled precision with advanced bending equipment, this process delivers high-quality, repeatable results for industries that demand accuracy and efficiency. What Is CNC Tube Forming? CNC (Computer Numerical Control) tube forming uses automated machines to bend, shape, and manipulate metal tubes […]

CNC Sheet Metal Forming 101

What is CNC Sheet Metal Forming? CNC sheet metal forming is a manufacturing process that uses computer-controlled machinery to bend, shape, and form flat metal sheets into three-dimensional parts. Unlike manual forming methods, CNC technology ensures consistent precision across every piece produced, making it ideal for both prototype development and high-volume production runs. Advantages of […]

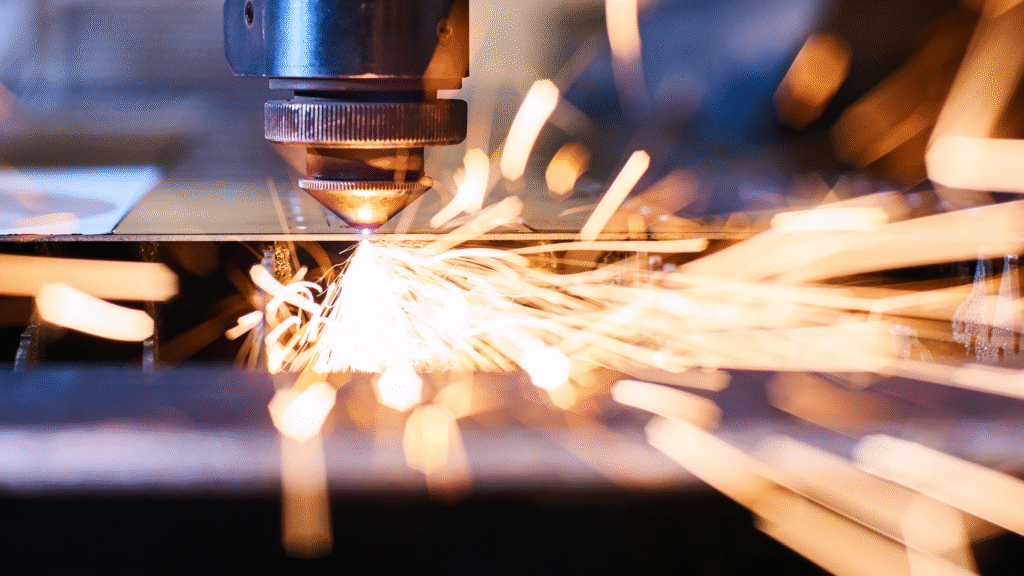

Aluminium Laser Cutting: Precision in High-Volume Manufacturing

Why Aluminium Laser Cutting Matters for High-Performance Manufacturing You’ve invested in designing strong, reliable parts. But what happens if the cutting process introduces burrs, warping, or inconsistent dimensions? Even the smallest imperfection can ripple through your entire production line — causing assembly issues, wasted materials, and costly delays. For manufacturers running high-volume program, […]

Robotic Welding vs Manual Welding: Making the Right Choice for Your Manufacturing Needs

Why Welding Method Matters in Modern Manufacturing In today’s competitive manufacturing landscape, welding isn’t just about joining metal — it’s about efficiency, consistency, safety, and cost control. The debate between robotic welding and manual welding is more relevant than ever as OEMs seek to balance productivity with flexibility. Understanding the strengths and limitations of each […]

Powder Coating vs. Paint: Which Finish is Best for Industrial Parts?

You’ve invested in precision-built parts for your equipment — but what happens if the finish can’t hold up? Rust, chips, and fading can turn a solid component into a weak link, costing you money and downtime. That’s why the decision between powder coating and paint is far more than cosmetic. It’s about protecting your investment […]